Circular Prestressing is basically utilized to indicate the prestressing of cicular structures, for example, pipes and tanks where the prestressing wires are twisted in circles. As opposed to this term, “linear prestressing” is utilized to integrate every single other kind of prestressing, where the cables can either be linear or bended, however not twisted in circles around a round structure. In most cases of the prestressed structures, the prestress is applied to the both longitudinally and circumferentially as well, the longitudinal prestress being the actually linear and the circumferential prestress being circular in nature.

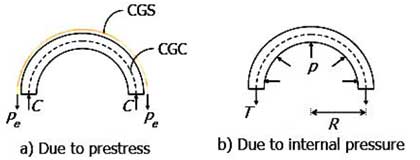

The circumferential prestressing opposes the hoop strain produced because of the inward pressure. The prestressing is carried out by wires or ligaments set spirally, or over segments of the boundary of the member. The wires or tendons lay exterior of the concrete center. Thus, the focal point of the prestressing steel (CGS) lies exterior of the center core segment.

At the point when the prestressed individuals are bended or curved, toward prestressing, the prestressing is chiefly known as circular prestressing. For instance, circumferential prestressing in structures like tunnels, channels, tanks, storehouses, regulation structures and other comparable structures is a kind of roundabout prestressing. In these structures, there can be prestressing in the longitudinal way (parallel to hub) also. Circular prestressing is additionally connected in domes, vaults and shells.

The circumferential prestressing opposes the hoop strain produced because of the interior weight. The prestressing is carried out by wires and tendons set spirally, or over segments of the perimeter of the member . The wires or the tendons lay outside the concrete centre.

Thus, the focal point of the prestressing steel (CGS) is outside the center concrete area. The hoop pressure produced is thought to be uniform over the density of a thin shell. Consequently, the pressure line (or Cline) lies at the focal point of the center concrete section (CGC). The accompanying portrayal demonstrates the interior forces under varying service conditions. The investigation is accomplished for a cut of unit length along the longitudinal bearing (parallel to the axis).

Fluid holding structures, for example, round funnels, circular pipes, tanks and weight vessels are properly matched for circular prestressing. The circumferential hoop compaction/compression instigated in concrete by prestressing offsets the hoop strain created because of the inward liquid pressure. A fortified concrete pressure pipe needs great amount of reinforcement to assure low-elastic or low tensile stresses bringing about a crack free structure. In any case, circular prestressing wipes out breaks and accommodates a sparing utilization of materials. Likewise, prestressing shields against shrinkage breaks in fluid holding structures.

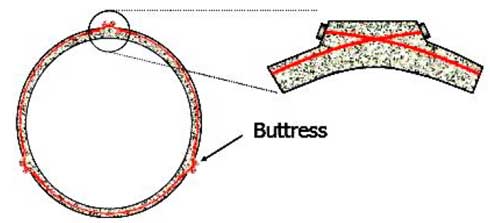

To eliminate the loss of prestress because of the friction friction, the prestressing should be carried out over sectors of the circumference. Buttresses are utilized for the anchorage of the tendons. The sketch below explains the buttresses along the circumference.