Objective: To ascertain the shear strength (ultimate shear stress) of the mild steel specimen supplied using double shear method.

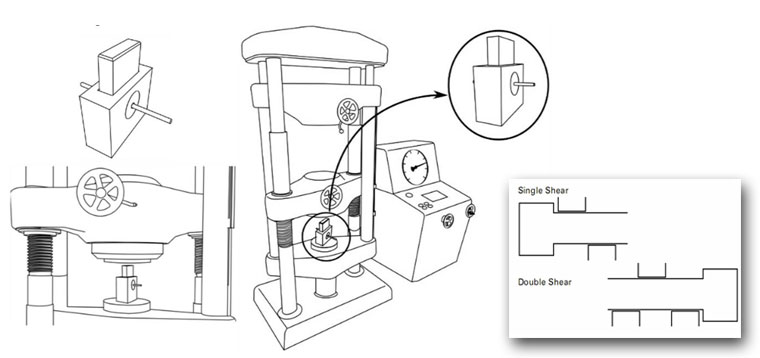

Equipment

- UTM

- Shear attachment to the UTM

- Shear dies

- Venire Calipers.

Theory and Principle

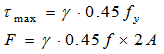

Shear strength of the material refers to the ultimate shear stress ( ![]() ) achieved by the sample which under double shear shown by:

) achieved by the sample which under double shear shown by:

![]()

Where,

F = Maximum load at which the specimen breaks, and

A = cross-sectional area of the specimen.

The load range to which the machine is to be set for the experimentation is chosen bases on the expected maximum load F to be exerted on the sample. This is premeditated from the yield stress fy and the factor of safety ![]() , as follows:

, as follows:

Permissible shear stress t for mild steel is,

![]()

Thus,

Process

Measure and mark down the dimensions of the sample. Compute the greatest load expected to be exerted on the sample utilizing the equation (2) and choose the load range to be utilized. Set the UTM for the chosen load range. Set the accurate set or dies to amass the shear attachment with the correct set of dies in it. Enclosure the sample in to the dies so that it projects correspondingly on both of the sides. Position the total bear assembly with the sample in it centrally over the baring plate on the lower table. Transport the lower cross- head close to the highest surface of the assembly. After that, float the lower table and then set the load pointer to nil. Exert the load slowly until the specimen breaks. Mark down the ultimate load exerted on the sample.

Observation

The observation is tabularized

Calculations

Range: Utilizing the equation (2) and assuming taking fy = 250 N/mm2 and =3 and, expected maximum load to be applied on the sample is,

F’ = 3×0.45×250/2A

Using equation (1) the ultimate shear stress is= F/2=___________

Result

Ultimate shear stress of the material be N/mn^2

Questions

1. State the differences between single shear and double shear.

2. State the differences between average shear stress and maximum shear stress.

3. Explain why Modulus of rigidity is not computed from shear test?

4. Give reasons for why structural component is designed chiefly by considering double shear strength?