Objective: Assessment of softening point of bitumen/tar.

Apparatus

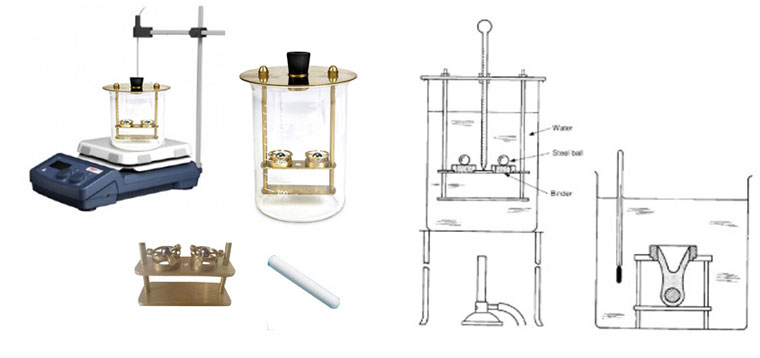

1. The ball and ring apparatus comprising of

(a) Steel balls-two numbers each of 9.5 mm dimensions with weight of 3.5 ± 0.05 g.

(b) Brass rings-two numbers with each with depth of 6.4 mm. The interior width at bottom and crest is 15.9mm and 17.5 mm correspondingly.

(c) Ball guides to monitor the shift ability of steel balls centrally.

(d) Support -that can support the rings in place and also permits for interruption of a thermometer. The distance amongst the base of the rings and the crest surface of the bottom plate of the support is 25mm.

2. Thermometer with the property to read upto 100° C with an correctness of 0.2° C.

3. Bath–heat resilient glass beaker with minimum of 85 mm in diameter &1220mm deep.

4. Stirrer

Theory

The point at which the bitumen or the tar is softened is the accurate temperature substance achieves specific degree of softening. As per IS: 334-1982, it is the precise temperature in ºC at which an average ball permits through a specimen of bitumen in a mould and discharges through a stature of 2.5 cm, when extensively warmed under water or glycerin at given circumstances of test. The binder must need to have adequate fluidity prior to its utilization in road applications. The determination of moderating point contributes to identify- the temperature up to which a bituminous binder has to be warmed for numerous road use utilizations. Softening point is assessed by help of ring and ball apparatus.

Procedure

- Preparation of experimentation specimen: First of all, heat up the material to the approximate temperature ranging between 75-100° C beyond its softening point; continue stirring until it is entirely fluid and exclusive of from air bubbles and water. If essential, filter it with help of IS sieve 30. Position the rings which were previously heated to a temperature resembling to that of the melted material, on a metal plate which has been thoroughly coated with a blend of equivalent parts of glycerine and dextrine. After letting it cool for about 30 minutes in air, level the material in the ring by eliminating the additional material with a heated and sharp knife.

- Perfectly amass the apparatus with the rings; thermometer and ball guides in suitable position.

- Fill up the bath with purified water to a stature of 50mm beyond the higher surface of the rings. The preliminary temperature has to be minimum of 5 degrees.

Note: Substitute water and use glycerine in those cases where the softening point is anticipated to be greater 80° C; the initial temperature maybe maintained at 35° C.

- Apply heat to the bath and blend the liquid so that the temperature increases at a unchanging rate of 5 ± 0.5 °C per minute.

- Since the temperature starts to augment the bituminous material will soften and the balls sink from side to side the rings containing a segment of the material with it.

- Mark down the temperature when to some extent of the steel balls with bituminous coating tads the base of the plate.

- Mark down the temperature when the second ball tads the end plate.

- The average of the two readings to the closest 0.5°C is stated as softening point.

Precautions

- We should not utilize distilled water as the heating medium.

(ii) At the time of the conduction of test, the apparatus cannot be exposed to vibrations.

(iii)The bulb of the thermometer has to be approximately at the same level as the rings.

Observations

| Temperature when the ball touches bottom, °C | 1 | 2 |

Results:

Softening point of bitumen / tar = °C

Recommended value:

Softening point shows the temperature at which binders retains the similar viscosity. Bituminous materials are exclusive of the melting point. Reasonably, the alteration of state from solid to liquid is steady over an extensive kind of temperature. Softening point has specific implication for materials to be utilized to flow at the time of service. Greater the softening point, minor the temperature vulnerability. Bitumen with greater softening point is favored in warmer places.