Objective: To assess the California Bearing Ratio (CBR) value of the subgrade soil.

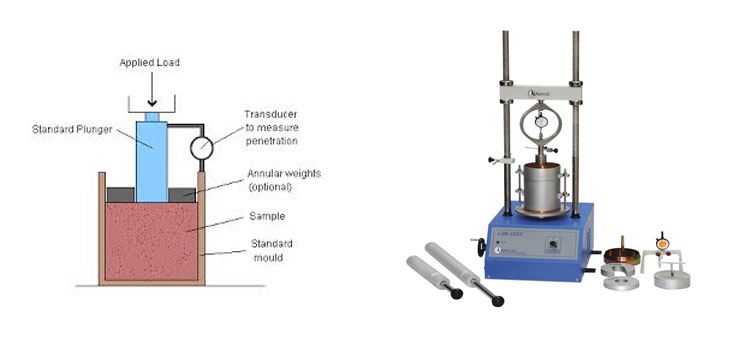

Apparatus

Loading machine-any compression could function at constant rate of 1.25mm per minute could be utilized. Cylindrical moulds- moulds of 150mm diameter and 175mm stature given with a collar of about 50mm length and removable punctured base. Compression rammer, surcharge weight-annular weights all of them of at least 2.5kg and 147mm diameter. IS sieve 20mm, Coarse filter paper and balance.

Theory

The California Bearing Ratio (CBR) test was founded by the California Division of Highways as a technique of categorizing and assessing soil- subgrade and base course substances for elastic pavements. CBR is an extent of resilience of a substance to infiltrate of standard plunger under measured thickness and humidity conditions. CBR test might be undertaken in remoulded or unobstructed specimen. Test comprises of leading a cylindrical plunger of 50mm diameter to infiltrate a pavement constituent material at 1.25mm/minute. The loads for 2.5mm and 5mm are logged. This load is articulated as a percentage of average load value at a corresponding distortion level to acquire CBR value.

Procedure

First of all, we have to sieve the specimen through 20mm IS sieve. Take 5kg of the specimen of soil sample. Pour water to the soil in the amount such that optimal dampness content or field humidity content is achieved. After the completion, soil and water are blended methodically. Spacer disc is positioned over the baseplate at the end of mould and a rough filter paper is put over the spacer disc. The primed soil water mix is separated into five. The mould is eviscerated and oil is applied. After this, we have to now fill one fifth of the mould with the primed soil. That coating is compressed by providing 56 evenly dispersed blows utilizing a hammer of weight 4.89kg. The crest layer of the compressed soil is then scratched. Once again, second layer is packed and process is carried out once again. After the completion of 3rd layer, collar is also connected to the mould and the process is carried out again and again. After fifth layer collar is detached and additional soil is hit off. Detach the base plate and overturn the mould. Then it is fastened to baseplate.

Surcharge weights of 2.5kg is kept on the crest surface of soil. Mould comprising sample is kept in position on the testing machine. The infiltration plunger is brought in interaction with the soil and a load of 4kg (seating load) is exerted leading to contact amongst soil and plunger is proven. Then dial readings are attuned to nil. Load is exerted such that the infiltration rate is 1.25mm per minute. Load at penetration of 0.5,1,1.5,2,2.5,3,4,5,7.5,10 and 12.5mm are marked down.

Standard Load values

| Penetration(mm) | Standard Load(kg) | Unit Standard Load(kg/cm2) |

| 2.5 | 1370 | 70 |

| 5 | 2055 | 105 |

| 7.5 | 2630 | 134 |

| 10.0 | 3180 | 162 |

| 12.5 | 3600 | 183 |

Observation:

Weight of soil taken =

Weight of surcharge =

Area of plunger, A =

Proving Ring Calibration Factor =

| Sl No. | Penetration(mm) | Proving dial reading | Load on plunger(kg) | Corrected load | Unit Load |

Result

California Bearing Ratio at 2.5mm penetration =

California Bearing Ratio at 5.0mm penetration =

California Bearing Ratio of subgrade soil =