To carry out an energy audit, many tasks are normally executed depending on the variety of the audit and the size and function of the building. Some of the tasks may have to be performed, diminished in scope, or even cancelled depending on the findings of other works. Thus, the execution of an energy audit is usually not a linear process and is more iterative. On the other hand, a normal procedure can be outlined for most structures.

Step 1: Building and Utility Data Analysis

The main reason for this step is to estimate the distinctiveness of the energy systems and the blueprints of energy usage for the structure. The building features could be composed from the architectural/ mechanical/electrical drawings and/or from debates with the building operators. The energy use patterns can be achieved from a combination of utility bills over many years. Different analysis of the chronological variation of the utility bills lets the energy auditor to decide any seasonal and weather effect on the structure energy usage. Some of the tasks that can be executed in this step are shown below, with the key objectives predictable from each task noted in the italics:

- Accumulate minimum 3 years of records of utility data [to recognize the chronological energy use pattern]

- Recognize the variety of fuels used (electricity, natural gas, oil, etc.) [to decide on the fuel type that accounts for the biggest energy use]

- Establish the patterns of fuel use by fuel type [to recognize the peak demand for energy use by fuel type]

- Comprehend utility rate structure (energy and demand rates) [to assess if the building is castigated for peak demand and if more economic fuel can be bought]

- Analyze the effect of weather on fuel consumption

- Perform utility energy use analysis by building type and size (building signature can be evaluated incorporating the energy use per unit area [to compare against typical indices]

Step 2: Walk-Through Survey

This step has to recognize probable energy savings techniques. The results of this step are imperative since they decide if the building warrants any additional energy auditing work. Some of the steps incorporated in this step are

- Recognize the customer’s queries and needs

- Check the current operating and upholding methodologies

- Decide on the current operating circumstances of main energy use tools (lighting, HVAC systems, motors, etc.)

- Approximate the tenancy, tools, and lighting (energy use density and hours of process)

Step 3: Baseline for Building Energy Use

The chief reason of this step is to expand base-case models that symbolize the current energy use and operating conditions for the structure. This model will be used as a indication to guess the energy savings because of the rightly chosen energy maintenance actions. The main errands to be executed during this step are:

- Attain and appraise architectural, mechanical, and electrical drawings

- Examine, test, and assess structure tools for competence, presentation, and reliability

- Attain all tenancy and operating routines for tools (including lighting and HVAC systems)

- Develop a foundation model for building structure energy use

- Standardize the baseline model with the usage of the utility data and/or metered data

Step 4: Evaluation of Energy-Saving Measures

In the 4th step, a list of economic energy preservation techniques is decided by using both energy savings and economic investigation. To attain this goal, the subsequent tasks are suggested:

- Arrange a comprehensive list of energy conservation actions (using the information gathered in the walk-through survey)

- Establish the energy savings because of the various energy conservation procedures relevant to the building by using the foundation energy use imitation model developed in Step 3

- Estimation of the original costs needed to execute the energy preservation procedures

- Evaluate the cost of individual energy management techniques using an cost-effective analysis method (simple payback or life-cycle cost analysis)

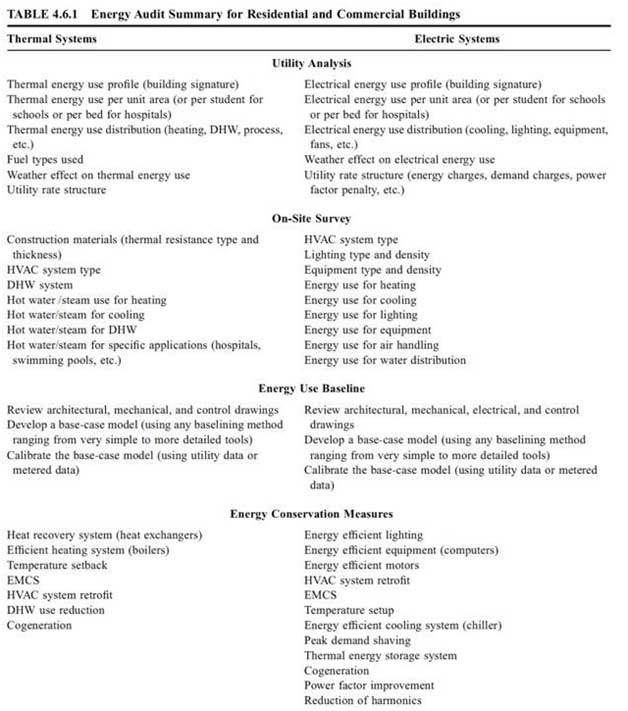

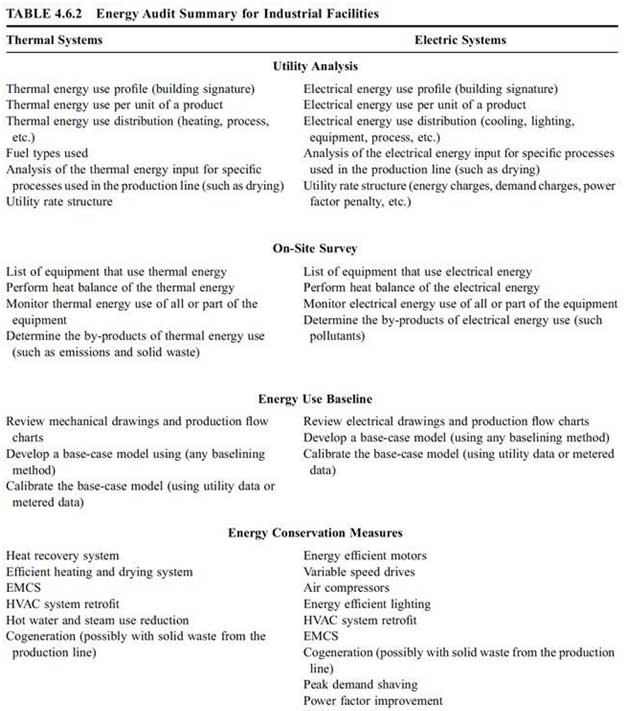

Tables 4.6.1 and 4.6.2 show the briefing of the energy audit processes recommended, respectively, for profitable buildings and for manufacturing facilities. Energy audits for thermal and electrical systems are estranged because they are characteristically subject to diverse utility rates.