Reactive power concrete (RPC) is:

- A composite material of ultra high quality with mechanical properties.

- Mixture of fiber strengthened, super plasticized, silica rage, bond and quartz sand with low water concrete proportion.

- Quartz sand utilized rather than normal total. Thus, these lines increments compressive quality.

Composition

- It is made out of comparative modulus of flexibility and size expanding homogeneity decreasing differential elastic strain.

- The material having the biggest molecule measure in RPC is the sand.

- The higher the thickness, the more noteworthy the quality and lower the porousness.

- Water bond proportion utilized as a part of RPC reaches from 0.15 to 0.25

- Strength more than 200MPa accomplished, cured at 90 degree Celsius.

Components with functions parameters

Components

- Sand

- Cement

- Quartz powder

- Silica fume

- Steel fibers

- Superplasticiser

Function Parameters

- Give power to total

- Binding substance

- Highest reactivity while heat-treating

- Filling the hollows

- Recover ductility

- Reduce water binding

Characteristics of Reactive Powder Concrete

- Compact Strenth

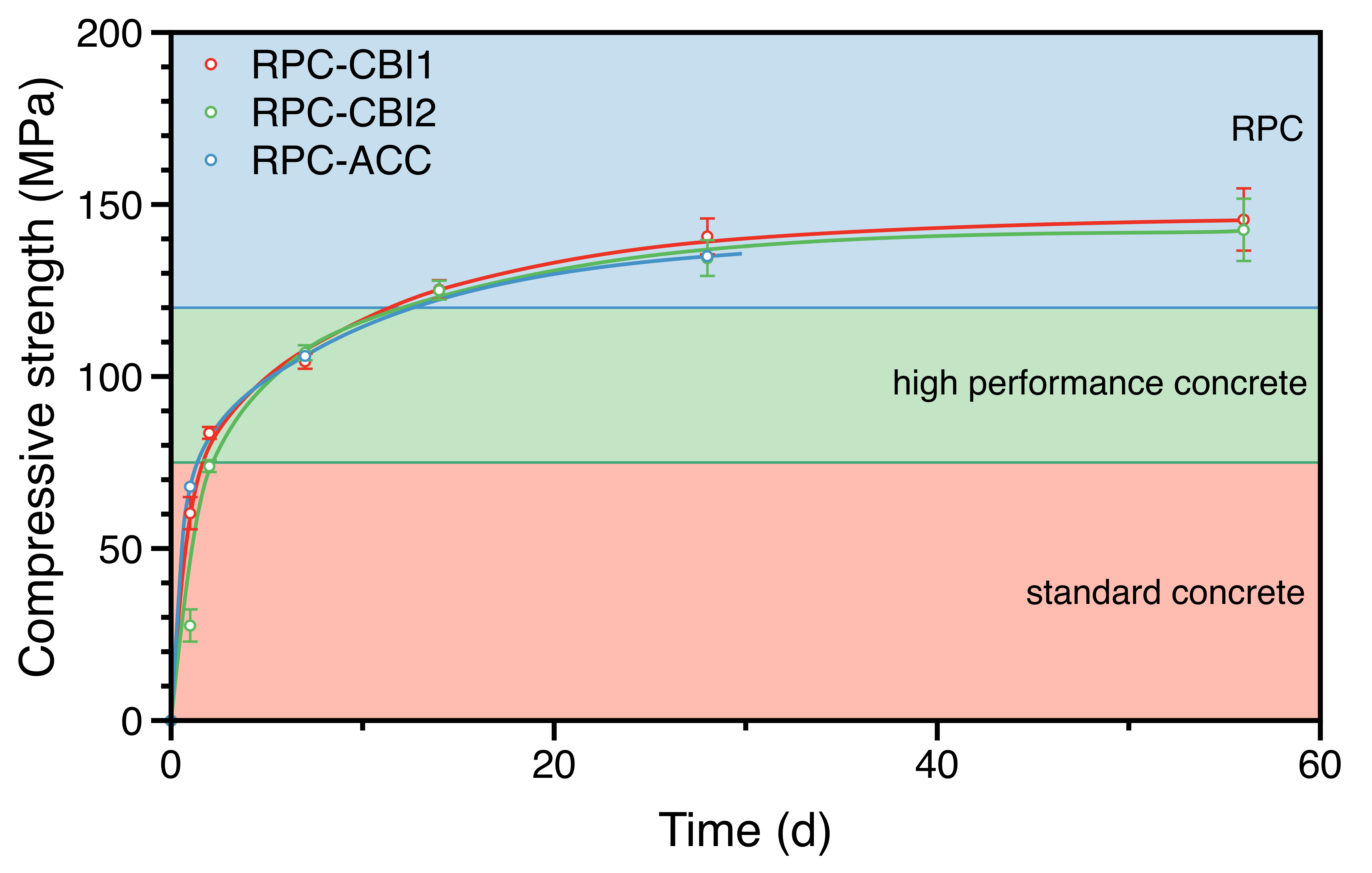

- Higher compressive strength than HPC

- It is a factor connected with toughness of substance.

- Highest compressive force of RPC is roughly 200MPa.

- Flexural Strength

- Plane RPC has maximum flextural strength than HPC

- By bringing forward steel fibers, RPC can attain high flextural strength.

- Water Absorption

- Water Permeability

- Resistance to Chloride Ion Penetration

- Expands when heat curing is done in solid

- Heat cured RPC show greater value than normal cured RPC.

- Homogenity

- enhanced by removing all coarse aggregates.

- Dry materials for use in RPC is lesser than 600 micro meter.

- Compactness

Appliance of pressure before and while concrete setting period.

- Microstructure

Microstructure of the cement hydrate could be altered by putting heat treatment while curing.

Application

- Sherbrooke Pedestrian Bridge

- Containment of nuclear waste:

- Used for separation and repression of nuclear wastes.

- It has been used for jamming & stabilization of repression waste.

Advantages

- It can possibly basically rival steel.

- Superior quality consolidated with higher shear limit result in critical dead load lessening.

- RPC can be utilized to oppose everything except direct essential tractable anxiety.

- Improved seismic execution by diminishing dormancy stack with lighter part.

- Low &non-interconnected porosity decreases mass exchange, making infiltration of fluid/gas non-existent.

Disadvantages

- Least overpriced parts of routine cement are wiped out by more costly components.

- RPC supplants steel in pressure individuals where sturdiness issues chance. So long haul properties are not yet known.