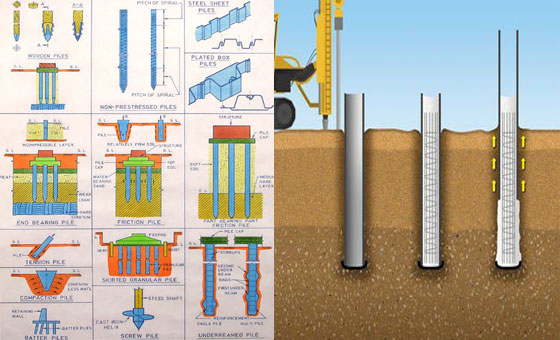

Classification based on transmission & functional nature

Based on transmission and functional nature, piles may be categorized into following types:

- Friction piles (cohesion piles )

- Combination of friction and cohesion piles

- End bearing piles (point bearing piles)

End bearing piles

These piles exchange their heap on to a firm stratum situated at a significant profundity beneath the base of the structure and they infer a large portion of their conveying limit from the infiltration resistance of the dirt at the toe of the pile(see figure 1). The pile carries on as a normal section and ought to be outlined accordingly. Indeed, even in powerless soil a pile won’t bomb by clasping and this impact require just be considered if part of the heap is unsupported, i.e. in the event that it is in either air or water. Load is transmitted to the dirt through grating or union. In any case, now and again, the dirt encompassing the heap may hold fast to the surface of the heap and causes “Negative Skin Friction” on the pile. This, occasionally have significant impact on the limit of the pile. Negative skin contact is created by the waste of the ground water and union of the dirt. The establishing profundity of the pile is affected by the aftereffects of the site examine on and soil test.

Friction or Cohesion piles

The carrying capacity is expressed chiefly from the bond or friction of the soil exposed with the shaft of the pile.

Cohesion Piles

These piles transmit the majority of their load to the soil through skin grinding or friction. This procedure of driving such piles near each other in gatherings significantly lessens the porosity and compressibility of the soil inside and around the gatherings. Along these lines piles of this classification are in some cases called compaction piles. Amid the way toward driving the load into the ground, the dirt gets to be distinctly formed and, thus loses some of its quality. In this way the load is not ready to exchange the correct measure of load which it is expected to instantly after it has been driven. More often than not, the dirt recovers some of its quality three to five months after it has been driven.

Friction Piles

Additionally, these piles also transfer their load to the earth through skin friction or grinding. The procedure of driving such piles does not compress the soil substantially. These types of pile foundations are usually also called as pile foundations.

Combination of Friction piles and cohesion piles

An augmentation of the end bearing pile when the bearing stratum is not hard, for example, firm earth. The heap is driven sufficiently far into the lower material to create satisfactory frictional resistance. A more distant variety of the end bearing heap is piles with expanded bearing ranges. This is accomplished by compelling a globule of cement into the delicate stratum promptly over the firm layer to give a developed base. A comparative impact is delivered with exhausted piles by framing an extensive cone or chime at the base with an extraordinary reaming apparatus. Exhausted piles which are given a chime have a high rigidity and can be utilized as pressure piles.

Classification of piles in regards to the type of material

On the basis of material used, piles may be classified as:

- Concrete piles

- Steel piles

- Composite Piles

- Timber piles

Apart from them there are other types of piles based on material used, which are as follows:

5. Steel Piles:

Made of parts as H, X or of thick pipes (see fig. 6). They are appropriate for taking care of and driving in long lengths. Their moderately little cross-sectional territory consolidated with their high quality makes entrance less demanding in firm soil. They can be effectively cut off or joined by welding. On the off chance that the pile is crashed into a dirt with low pH esteem, then there is a danger of consumption, yet danger of erosion is not as extraordinary as one may think. In spite of the fact that tar covering or cathodic insurance can be utilized in changeless works.

It is regular to take into account a measure of consumption in outline by just over dimensioning the cross-sectional region of the steel pile. Along these lines the erosion procedure can be drawn out up to 50 years. Regularly the speed of erosion is 0.2-0.5 mm/year and, in outline, this esteem can be taken as 1mm/year

- X-cross section

- H- cross section

- Steel Pipes

Advantages:

- The piles have easy utilization and could be easily cut to the desired length.

- Could be driven from end to end of dense layers.

- Can be driven hard and in very long lengths.

- Can lift heavy loads.

Disadvantages:

- Not very cost effective

- Deviates easily while driving

- The piles will corrode

6. Composite Piles

It refers to the blend of various materials in the same of pile. As shown earlier, part of a timber pile which is established ahead of the ground water can be prone to to insect attack and decay and corrosion. To steer clear of this, concrete or steel pile is utilized ahead of the ground water level, while wood pile is established under the ground water level.

Classification based on regards to soil

Based on how its driven on soil, the pile may be classified into following two types:

- Driven Piles

- Bored Piles