A Rubber-tyred metro is a type of fast transit system framework that uses a blend of street and rail innovation. The vehicles have wheels with rubber tires like a transport, however utilizing an arrangement of two parallel concrete or creased steel rollways, each one of them with the width of a tire. Vehicles have wheels with rubber tyres which keep running inside a guide route for footing, and additionally customary railroad steel wheels with the flanges on steel tracks for direction.

- Rubber tyred Metros were initially developed by the Regie Autonome des Transports Parisiens (RATP)

- Rubber tyred metro innovation was initially connected to the Paris Metro, created by Michelin

- The main totally rubber tyred metro framework was implicit Montréal, Canada

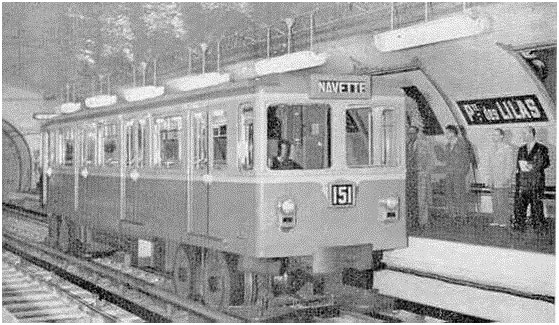

Image: First rubber tyred metro in Paris

Advantages

- Smooth ride (with small “jarring” around)?

- Speedier acceleration

- Shorter braking separations, permitting trains to be flagged nearer together

- The capacity to climb or plunge more extreme inclines (~gradient 13%) than would be practical with traditional rail tracks.

- Calm ride in outdoors (for occupants and those outside the train)

Disadvantages

- Greater energy consumption

- Not very economic to build, maintain and install

- Greater quantity if additional heat is generated

Hindrances

- Higher vitality utilization than steel-on-steel

- A bigger amount of abundance warmth is produced

- Costly to fabricate, introduce and keep up.