The installment procedure and strategy for installment are similarly critical variables as of the plan procedure of pile foundations. Pile establishment strategies are establishment by pile mallet and exhausting by mechanical wood screw.

Keeping in mind the end goal to stay away from harms to the piles, amid designing, installation methods and establishment gears ought to be precisely chosen.

On the off chance that installation is to be done utilizing pile hammer, then the accompanying variables ought to be taken into thought:

- The size and the mass of the pile

- The driving resistance which must be overcome to accomplish the outline infiltration

- The accessible space and head room on the site

- The accessibility of cranes and

- The commotion limitations which might be in drive in the region.

Pile driving techniques (Displacement piles)

Methods or techniques of pile driving are listed below:

- Dropping weight

- Explosion

- Vibration

- Jacking (restricted to micro-pilling)

- Jetting

Drop hammers

A hammer with the tentative weight of the pile is higher-ed to a appropriate height in a guide and suspended so that it strikes the pile head. This is an easy procedure form of hammer utilized in conjunction with test piling and light fames, whilst it may not be cost-effective to bring a steam boiler r on to the site to drive very limited quantity of piles.

Two main kinds of drop hammer

- Single-acting steam which is also basically known as compressed-air includes a massive mass in the shape of a cylinder. Steam or compressed air released into to the cylinder raises it above the settled piston rod. At the apex of the stroke, or at a smaller depth which could be monitored by the operator, the steam is cut off and thus the cylinder is suspended freely on the top of the pile helmet.

- Double-acting pile hammers could be led by steam or compacted air. A pilling frame is not necessary with this kind of hammer which could be joined to the apex of the pile by leg-guides, the pile being held up by a timber framework. When utilized with a pile frame, back guides are fastened to the hammer to connect with leaders, and just short leg-guides are utilized to stop the hammer from moving moderately to the apex of the pile. Double-acting hammers are basically utilized for sheet pile driving.

Pile driving by vibrating

Vibratory hammers are basically electrically powered. In some cases they are also hydraulically powered and incorporates contra-rotating eccentric masses inside a housing connecting to the pile head. The amplitude of the vibration is enough to dismantle the skin friction on the corners of the pile. Vibratory techniques are most applied to sand surface or gravelly soil.

Jetting

To contribute in the infiltration of piles in to sand or sandy gravel, water jetting method can be applied. On the other hand, the technique has very restricted effect in firm to rigid clays or any soil incorporating much coarse gravel, boulders or cobbles.

Boring Methods (Non-displacement piles)

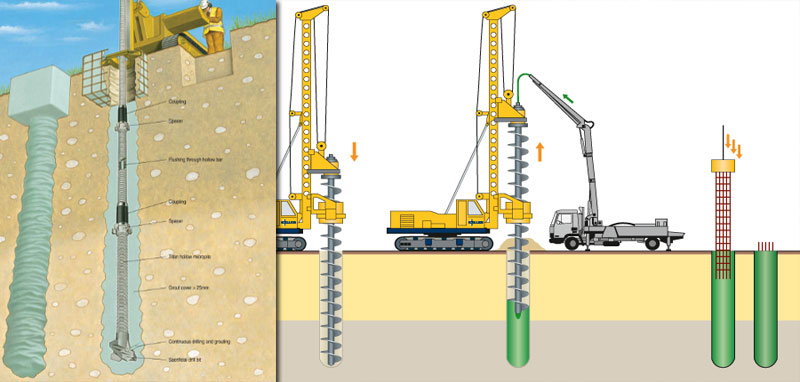

Continuous Flight Auger (CFA)

The techniques is specifically effective on soft ground and leads to establish an assortment of bored piles of different diameters that are capable to infiltrate a multiple level of soil conditions. However, for triumphant operation of rotary auger the soil has to be practically free of tree roots, cobbles, and boulders.

Underreaming

A specific property of auger bored piles which is usually utilized to lead to exploit the bearing capability of appropriate strata by giving an amplified base.