Aim:

- To ascertain the Darcy’s and Chezy’s constant for the specified pipes

- To plot the specified graph:

Darcy’s constant ‘f’ vs Reynold’s number

Chezy’s constant ‘C’ vs Reynold’s number

Equipment:

- a) Pipes of 15, 20, 25 and 32 mm diameters ‘D’ of longitude ‘L’ 3 m with flow control valve in all of the pipe. Upstream and downstream pressure feed pipes as manifold are given for the specified measurement of pressure head with control valves located on a common place for trouble-free operation.

- b) Measuring tank size 0.6 x 0.6 x 0.8 meter with overflow arrangement, gauge glass, drain valve and scale agreement.

- c) U tube Differential Mercury Manometer of Range 0.5 m and Scale graduations: 1mm to assess the loss of head.

- c) Stop watch.

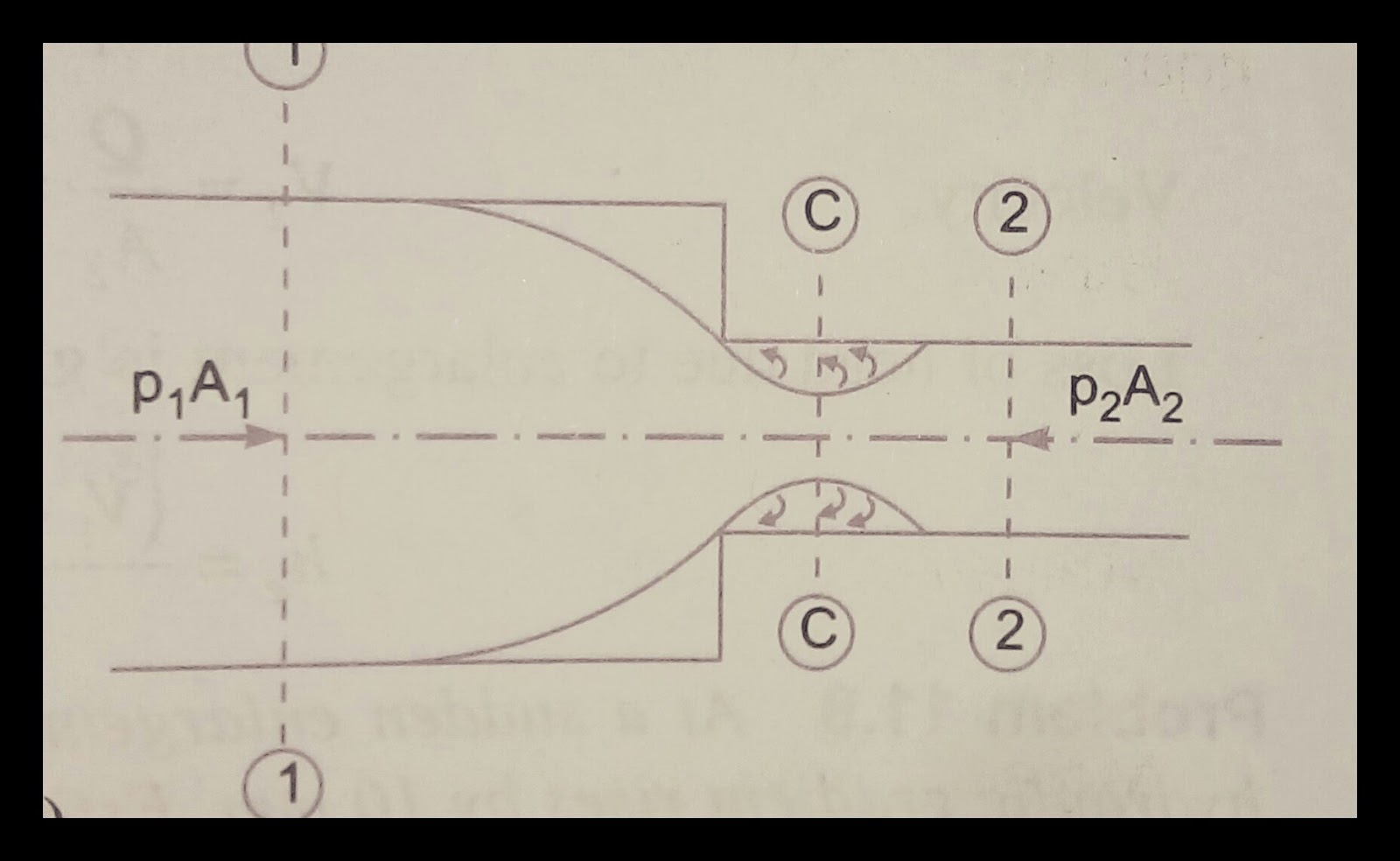

Theory:

When the liquid flows through the pipeline, a velocity gradient and thus shear stress is created in the water because of glutinous action leading to loss of energy. This loss is also called as frictional loss.

Let water to flow from the specified pipe and assess the head loss because of friction as HHg cm of mercury with the utilization of manometer linked at a identified distance of L cm. The actual discharge Qa through the pipe is determined by noting the period for gathering h cm of water in the measuring tank.

Actual discharge

Where

Hw – HHg * 12.6 cm of water.

L – Test length in cm.

V – Velocity of water inside the pipe

D – Inside diameter of pipe

Chezy’s constant C can be calculated from the relationship

Where

V – Velocity of water inside the pipe line cm/s.

i – Hydraulic gradient, Hw / L

m – D/4 – Hydraulic mean depth (ie. Cross sectional area Where

Hw – HHg * 12.6 cm of water.

L – Test length in cm.

V – Velocity of water inside the pipe

D – Inside diameter of pipe

Chezy’s constant C can be calculated from the relationship

Where

V – Velocity of water inside the pipe line cm/s.

i – Hydraulic gradient, Hw / L

m – D/4 – Hydraulic mean depth (ie. Cross sectional area wetted perimeter).

Reynold’s number for flow through the pipe line is calculated as,

Re = (? / ? ) V D

Where,

? – Mass density of water (1000 kg/m3 at 300 C.)

V – Velocity of water inside the pipe

D – Diameter of pipe

? -Absolute (dynamic) viscosity of water and is equal to7.82 * 10 – 4 kg/m.s. at 300C.

Process:

- Attach the mercury manometer to the pressure tappings at the bottoms of the test longitude of pipe and close all the valves (pipe line & manometer).

- Unbolt the needle valves of the manometer & pressure tapping. Make sure that the manometer is in place.

iii. Unbolt the inlet valve completely and regulate the opening valve of the chosen pipeline in which the trial has to be carried, to mark the utmost possible head difference (HHg) of the mercury column. Split the value (HHg) by seven to fasten the steps in the pressure disparity for the seven sets of readings.

- Regulate the outlet valve to obtain the requisite pressure disparity in the manometer and make a note of down the readings of manometer.

- Keep the record of the time in seconds to gather water for a rise of h cm in the tank two times as t1and t2. If the distinction in readings is greater than 10%, get a third reading within the range.

- Carry on the process again and again for the trial for different manometer readings.

Calculations and Graphs

Arrange comprehensive sample computation for one set of readings as specified in the principle. Compute the outstanding sets of readings and tabularize them. Illustrate the necessary graphs utilizing the data tabularized with appropriate scale.

- i) Darcy’s constant ‘f’ vs Reynold’s number

- ii) Chezy’s constant ‘C’ vs Reynold’s number

Maintenance:

After the completion of the experiment shut the inlet valve and unlock all the gate valves & needle valves after that have them closed again.

Now, deplete the water from measuring tank after the completion of the experiment.

Now, deplete the mercury from manometer by breaching the drain plug given at the bottom after two or three months and disinfect the glass tubes with water and soap and then fasten the drain plug and pour the mercury.

Observation:

Results:

Inference: