We can define Composite material as multi level material, created by amalgamation of different materials contradictory in composition which stay bonded collectively, however hold their properties and individual identity exclusive any kind of chemical reactions.

The composite substances don’t dissolve, however they are entirely merged with one another. They uphold an border between one another & act in the concrete to deliver more improvised unambiguous or synergistic property which is not accessible by any of the original singular component acting individually.

Classification

We can classify the composite materials broadly into natural & synthetic composites. The figure below shows the systematic classification.

As we see in the phase composition which is usually unaccompanied in the majority composite ingredients is inserts into the another substance also called as matrix.

The division dependent on the plastic matrix is thermosetting and thermoplastic.

The constituents of composite materials

The composite materials are created of different constituent materials which can be categorized as:

- Matrix

- Reinforcement

- Fiber matrix Inter phase

- Fillers

Matrix

It is also known as binder. The phase that gets the inserts in the phase composition is the continuous phase & is known as the matrix.

Example– polymer, metals, ceramics

Reinforcement

These are the materials which essentially give the strength, stiffness & other important mechanical characteristics to the composite materials.

Example– Glass, Jute fibers, Boron

Fiber-matrix Inter phase

The inter phase between the matrix and the fiber can be identified with ease. it is the properties and behavior pattern of the inter phase that by and large controls the characteristics of the composites. The important function of inter phase is to transfer and dispense the weight on matrix to the fortification.

Fillers & additives

Fillers are added to the polymeric matrix for given reasons:

- Cost effective

- Amplifies the stiffness

- Lessen mold shrinkage.

- Control glueyness.

- Create smooth surface.

These fillers have to be motionless & their existence in a polymeric matrix cannot have any impact on the processing & polymerization.

Matrix

Definition

The phase that gets the inserts in phase composition is continuous phase & is are known as matrix. They are also known as binders. The matrix material applied for the process of fabrication of composites material are by and large polymer & normally known as Resin.

Functions

The functions of matrix or binders are as follows:

- a) It provides mould-ability or form to composite.

- b) It presents the composite materials commonly with resistance to unfavorable environment.

- c) It also protects the reinforcement from unfavorable vicinity.

Types

The materials prominently used for the matrix are plastic, rubbers, ceramic & metals.

Plastic matrix based composite materials now have more than 95% of all the composite substances in use currently. Both of the Thermoplastic & Thermosetting substances are utilized as matrix materials.

Amid these all plastic material we are concerned in the matrix built up of the Thermoplastic composite with their intrinsic characteristics which can add to composite materials. Some of the thermoplastic materials are discussed.

Low density Polythylene

The polyethylene is created from pure ethylene as a result of high pressure techniques

These polymers have outstanding properties that are needed for matrix or binders which are:

Mechanical Properties:

Specific Gravity = 0.91 – 0.93

Processing temp = 180-2120 F.

Tensile strength = 0.9 – 2.5 x 103 psi

Impact strength = 0.2-12 ftlb/inch

Chemical properties:

High moisture Proof

Chemical stability

Resistance to the actions of micro-organism.

It has great stability toward varying Corrosive medium.

Applications –

These PE is utilized pipe which has been utilized for transportation of different types of liquids due to their greater degree of resistance to corrosive materials.

High density Polythylene

This polyethylene is createdd from pure ethylene as the outcome of low pressure techniques

This polymer has brilliant characteristics that are needed for binders or matrixes. These are:

Mechanical properties :

Specific Gravity = 0.94 – 0.96

Tensile strength = 2.9-5.4 x 103 psi

Impact strength = 0.4 – 14 ftlb/inch

Processing temp = 175 – 2500F

Chemical Properties:

Humidity proof.

Chemical steadiness

Resistance to activities of micro-organism.

High stability towards varying corrosive medium.

POLYPROPYLENE

Polymerisation of propylene is taken out in vicinity of the proper heterogeneous catalyst to create polypropylene.

Polypropylene has been known to have uncommon blend of brilliant physical, mechanical, thermal, electrical & chemical characteristics with exceptional high temperature resistance. These characteristics’ are used in matrix.

Mechanical Properties

Specific Gravity = 0.90 – 0.91

Tensile Strength = 4.5 – 6 x 103 psi

Impact strength = 0.4 – 12 ftlb/inch

Processing temp. = 225 – 300o F

Chemical Properties

The PP is most likely lightest know industrial polymer.

Polypropylene displays high stiffness, rigidity & tensile nature due to high crystalline.

Poly propylene is resistance to different other chemicals like alkali acid

It also has good humidity resistance.

Applications

Because of high degree of strength rigidity, temperature resistance & chemical resistance pp is appropriate to be utilized in the manufacture of chemical & biological attacks.

Nylons – 6 or perlon – l

A polyamide intimately associated is Nylon known as Perlon – L or Nylon – 6 is dependent on a polymeric fiber form only one ingredient caprolactum NH – (CH)5 – CO giving polymer it is primed by extended heating of w – amino caprolactum at 250 – 278 C. Nylon is mostly utilized in thermoplastic composite due to the presence of immersion or double bonds in its structures.

Mechanical Properties :

Specific Gravity = 1.14 Tensile Strength = 12.5 x 103 psi

Impact Strength = 2.0 – 5.0 ftlb/inch Processing Temp. =180 – 300 o F

Chemical Properties

High Solvent Resistance

High Biological Resistance

High Toughness and Elasticity

Applications

Nylon is utilized in the creation of transmission belts, link belts.

Reinforcement

Fibers are the chief material in the fiber reinforcement composite substances. .

Definition

It is materials which give the strength, rigidity & other mechanical characteristics to the composite materials.

Function

The reinforcement are utilized for the improvement of the structural properties of the materials. They could be successive in form of fiber, filament or discontinuous in varieties of flakes or whiskers.

The reinforcement amplifies the proportion of strength to density & stiffness to density.

It improves the formability & electrical prop.

It also amplifies the resistance to fatigue, ruptures, and corrosions to reduce the cost.

Types of reinforcements

Reinforcement can be categorized into 5 kinds:

- Mineral reinforcement: The mineral fillers by large applied are CaCo3, Silica, alumina etc.

- Hybrid reinforcement: In case of hybrid composite two or more high performance reinforcements are blended with each other.

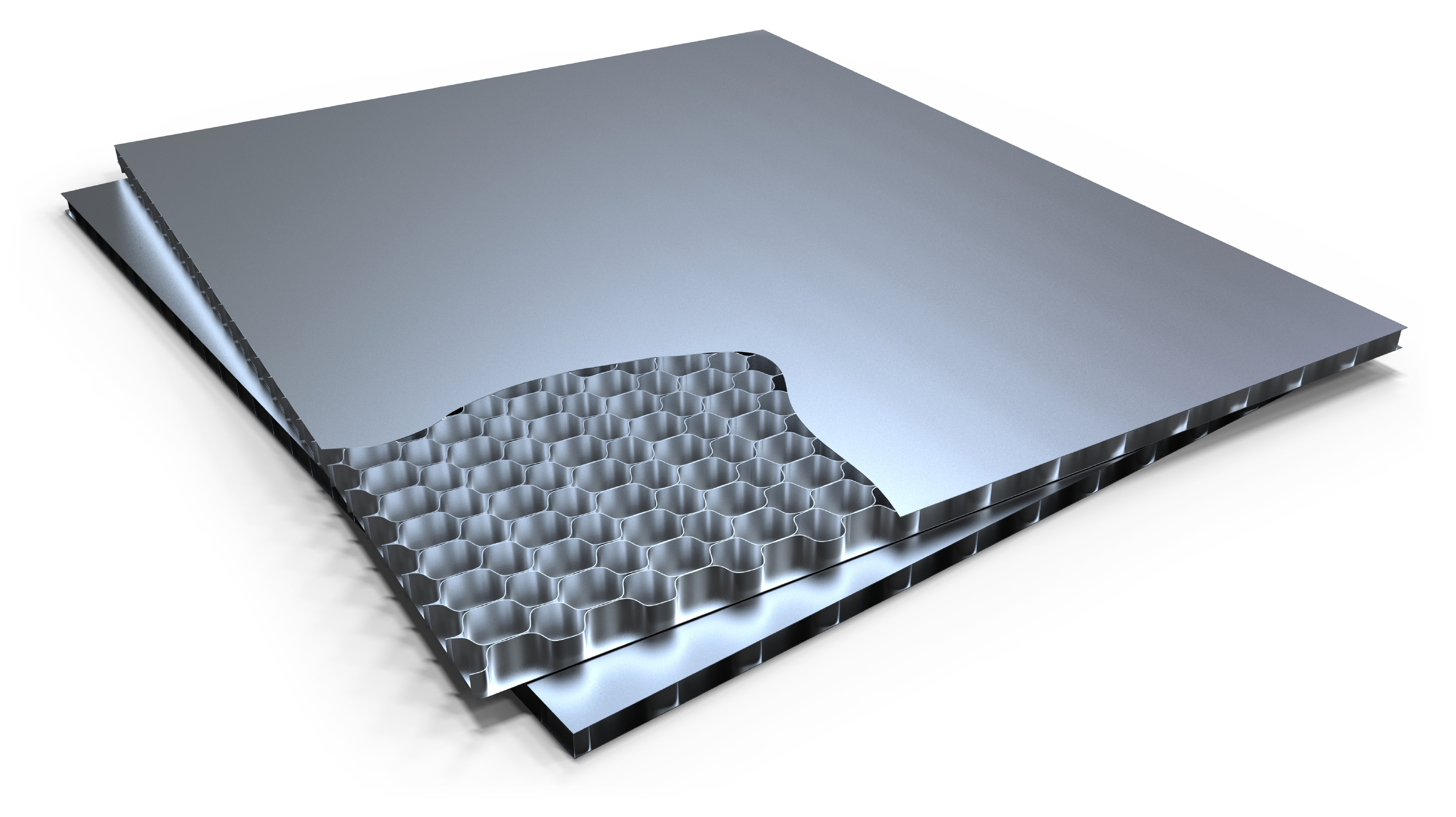

- Sandwich Reinforcement: Composite structure including of a thermoplastic core sandwich among the two metal pieces or levels Examples: – steel – pp – steel Al – Nr – Al.

- Metal filled thermoplastics: Even though plastics are thermal and electrical insulators, they can be made conductor by the introduction of conductive or even metallic fillers.

- Organic & inorganic reinforcements: Organic or inorganic fibers like the carbon, glass have been extensively utilized with plastic chiefly to recover mechanical strengths and the tensile modulus.

Here are some kind of fibers which are utilized in reinforcement:

- Glass Fiber

- Carbon Fibers

- Boron Fibers

- Kelvar Fibers

- Jute

Fiber-Matrix Interphase

The interphase among the matrix and the fiber could be identified with ease, it is the characteristics and the properties of the interphase that generally manipulates the properties of the composite materials. The quantity of composite cannot attained by any of the components acting individually.

Coupling Agents:

We can define coupling agents primarily as materials that improvises the adhesive bond of contradictory surfaces, this must engross an addition in true adhesion, and however, it may also include better wetting, theology & other handling characteristics.

The following are some of the examples of coupling agents:

- Silanes

- Titonates

Application of Thermoplastic Composites

- The knee braces molded from polyphenylene sulfide composite as shown in the figure above.

- Jallar and Mural are made of Jute-Thermoplastic Composite

- Street lamps and Garden fences are constructed of Jute Thermoplastic Composite

- Planters are made of Jute thermoplastic composite